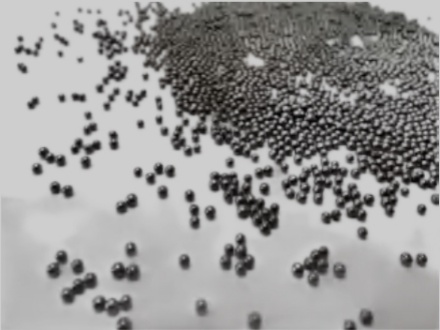

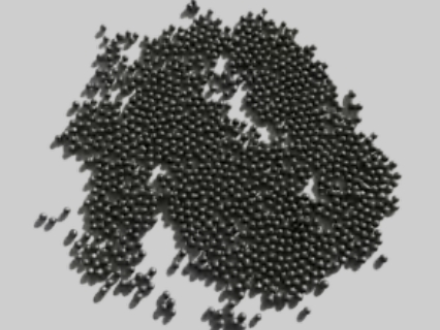

1.合金钢丸是由高质量的钢碎料及废钢,电炉加至合金元素熔化,调节钢水含量成分。然后在高压水喷射式或者用离心物化造粒使钢水形 成小球状。形成的丸体再次加热以净化匀质,然后进行淬火处理。淬火后的丸体在熔炉内进行烘干并重新加热回火以达到适当的硬度, 回火处理的钢丸通过机械筛网被分选成符合SAE标准的11个等级型号、以用于抛丸设备。

1. Alloy steel pellets are made of high-quality steel scraps and scrap, which are added to alloy elements by electric furnace to melt and adjust the composition of molten steel content. Then the molten steel is formed into small balls by high-pressure water injection or by centrifugal physicochemical granulation. The formed pellets are reheated to purify the homogeneity and then quenched. The hardened pellets are dried in the furnace and reheated to achieve the appropriate hardness. The tempered pellets are sorted through a mechanical screen into 11 SAE- compliant grades for use in shot blasting equipment.

扫一扫咨询微信客服

扫一扫咨询微信客服